UMP Technika produces high-quality hydraulic biomass briquette press options. Check out our range and fill out the contact form below to get started.

Our Biomass Briquetting Solutions

Have a Question?

CONTACT USBest Materials for Biomass Briquettes

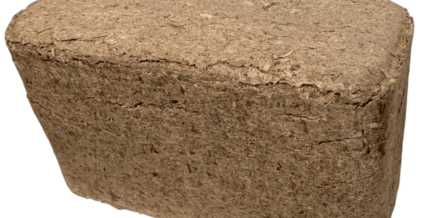

What goes in a biomass brick press? Below are some materials you can recycle for profit using a biomass briquette press machine:

- Straw. A corn stalk briquette-making machine processes straw, corn stalks, and other organic waste into bricks that can be used for feed or as fuel.

- Hay. Turn excess hay into a corn stalk briquette. This can be sold to agricultural companies.

- Tobacco. Tobacco offcuts and scraps can be safely recycled as a fuel source.

- Nutshells. Inconvenient waste like nutshells can be collected, compressed, and repurposed using a biomass press machine.

- Peat. Peat waste is an excellent material for fuel bricks. Compact it alongside other materials with a sawdust biomass press.

- Miscanthus. Garden waste like miscanthus is suitable for a corn stalk briquette-making machine and can be resold as feed.

- Shells from legumes. Legume shells are easy to repurpose as fuel or food using a biomass briquetting press.

- Cotton wool. Stop paying to dispose of cotton wool scraps. Press them along with other materials and resell them as fuel.

- Flax. Waste flax can be processed using a straw briquette press and turned into winter food for livestock.

Learn more about what you can recycle with a biomass briquetting press – contact us today.

Why Should You Consider Making Biomass Briquettes?

What are the main advantages of using a corn stalk briquette-making machine? Your business can save money, become more efficient, and improve its environmental credentials by repurposing waste.

Easier to Transport and Resell

A biomass press machine compacts waste that would fill several bags into small, manageable bricks. These are easy to store and attractive to buyers as they take up less space.

Compressed Biomass is More Calorific

The high-density bricks produced by our superior hydraulic biomass briquetting press machines are intensely calorific. This helps them burn longer than conventional fuel like logs. It also makes bricks efficient as animal feed.

Superb Combustion Material

Materials like peat are superb fuel sources and shouldn’t be sent to landfills. Instead, you can sell leftover peat and other organic matter as fuel when they’ve been compacted by a biomass briquette press machine.

Appropriate as Agricultural Feed

A corn stalk briquette-making machine can produce high-quality, long-lasting feed for livestock like chickens. Turn your edible organic scraps into a profitable corn stalk briquette with our hydraulic straw briquette press.

Purpose of Biomass Briquettes

Briquettes are used as fuel by many businesses. They can power commercial boilers or industrial stoves more efficiently than logs. They’re also popular among consumers for use in BBQs and fire pits or as winter fuel for a fireplace.

Find your ideal customer nearby and profit from your waste using a biomass briquetting press.

Need more information?

CONTACT USOur Briquetting Machines for Other Materials

If your shop or factory uses works with multiple materials, good news: we offer recycling solutions across the board. In addition to a biomass briquette machine, you might consider:

Wood scraps and sawdust are great fuel sources. Compact bricks burn for longer than logs and are popular for commercial and home applications. Alternatively, try our combined sawdust biomass press.

We all have waste paper. Save yourself the hassle of shredding it and filling huge, lightweight bags for disposal. Turn it into fuel bricks using our hydraulic paper briquette presses.

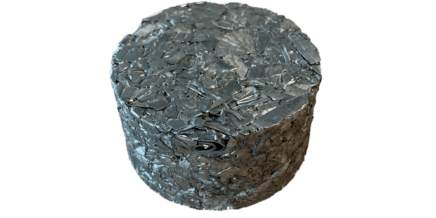

Metal Briquetting Machines

Metal offcuts are expensive to store and dispose of. Turn your metal scraps into money with our hydraulic metal briquette machines.

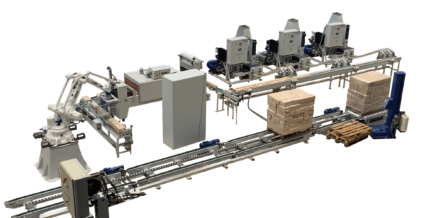

Automated Briquette Packing Solutions

Make your life easier – have your scraps condensed and packaged neatly for your new customers. Our automated briquette packing solutions transform your waste into attractive fuel bricks for easy resale.

Advantages of Biomass Briquetting

- Reduces volume. Who needs bags of waste piling up? A biomass briquetting press helps keep your workplace tidy.

- Cuts dust emissions. Protect your workers from hazardous dust with a sawdust briquette press. Increases density. Dense, calorific briquettes burn for longer, making them a popular fuel source.

- Reduces fire hazards. Cut fire and explosion hazards around your workplace by compacting flammable organic matter.

- Easier to handle residue. Who wants organic residue on their hands? Our hydraulic biomass press machine takes care of it all.

- Cuts disposal costs. Stop paying someone else to take your waste. Compress it into a commodity and start shipping it out.

- Cuts transport & storage costs. Save on waste storage and transportation by making compact fuel bricks.

Learn more and find your perfect press – contact UMP Technika by filling out the form below.

Frequently Asked Questions

If you are considering purchasing one of our briquetting presses and you still have some questions, don’t worry. We’ve prepared a list of our most frequently asked questions to try and give you a better insight.

Is a hydraulic or manual briquette press better?

A hydraulic option offers more power and saves time compared to manual models.

What is the greatest advantage of briquette over loose biomass burning?

Briquettes are easier to store and transport, they burn for longer, and burning is easier to control.

Can you use briquettes for livestock feed?

Yes – depending on the material. Briquettes for livestock feed need to be made of non-toxic waste like corn stalks or straw.