With an industrial shredder, you can condense large amounts of leftover wood, plastic, metal turnings, or whatever materials your factory works with into compact, manageable piles for disposal. Shredding your industrial waste is the best way to keep your property free of hazardous clutter and streamline your disposal process.

Read on below for everything you need to know about industrial shredders for sale.

Types of Industrial Shredders by Material

Wood is one of the most common materials put into industrial shredders. Depending on the combination of shredders you use, you could end up with wood chips or sawdust. Using our hydraulic press, you can convert your wood scraps into high value briquettes.

Suppose your factory or industrial property is drowning in paper waste that needs to be easily recycled. In that case, our heavy-duty shredders are more than powerful enough to get the job done. Turn your paper scraps into manageable shreds that are optimal for recycling.

Cardboard can also be easily broken down into particles using our equipment that are easier to handle. Most of our industrial shredders can be adjusted to work with any of these common factory waste materials.

Industrial Plastic Shredding Machines

Plastic is an incredibly common manufacturing material, and it’s important to recycle it where you can. That’s why UMP Technika is committed to providing plastic shredding equipment to help business and factory owners manage their excess plastic with ease.

Metal is a tough material, and it’s notoriously difficult to shred. But it’s still no match for UMP Technika’s state-of-the-art industrial shredders. Ask a representative about optimizing your shredder for use with metal waste. No need to spend precious time and energy handling large amounts of rigid metal with our powerful machinery on hand.

Recently, the demand for a good hay & straw shredders has grown immensely. Biomass is the leftover waste from organic materials, such as hay, straw, leaves, roots, and stalks from plants. If you process a lot of plant material and need to manage your biomass waste, UMP Technika has a solution to take care of your business.

Have a Question?

CONTACT USOur Industrial Shredding Machines

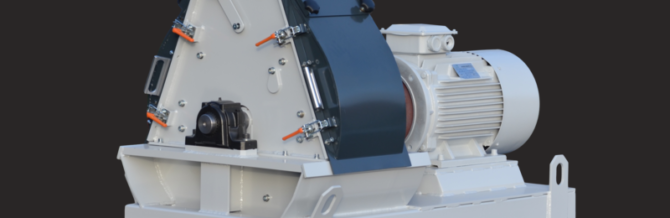

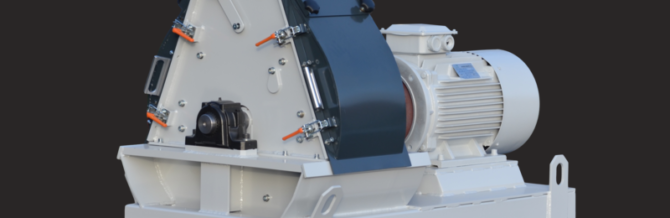

Our single-shaft shredders use a vertical feed hopper with a single rotor and hydraulic ram system where users can insert their material to be shredded. Whether your factory waste consists of wood, metal, paper, or plastic, with the correct specifications in place, the powerful industrial shredder teeth in these machines will have no problem getting the job done.

Horizontal feed shredders use rollers rather than hydraulic rams to feed material into the rotor. This system allows shredding of longer boards and cutoffs at a much higher volume than vertical feed shredders. Vibrating conveyor transports material to the shredder where feeder rotors pull it against a high speed shredding rotor.

Double Shaft Shredders

Different to the single-shaft model, the double-shaft shredder uses two shafts to pull and shred the material simultaneously. This is perfect for pre-shredding of bulk and difficult to manage materials.

If top quality fine shredding is what you are after, a Hammer Mill is what your factory needs. Whether creating uniform sawdust from wood chips, or turning raw materials into fine powder we have the solution.

Our machinery is the ideal fix for industrial properties with plenty of straw and hay with hidden potential value which can be unlocked by turning it to pellets or briquettes. The conveyor system makes it easy to load and buffer multiple bales for shredding to lose bedding.

Need more information?

CONTACT USAdvantages of Using our Shredders

UMP Technika is one of the leading shredding machine manufacturers in the industry. As such, there are a few key aspects that set our company apart from the competition and make our industrial recycling shredders better than the rest. Here are just a few reasons why you should always trust UMP Technika as your preferred shredding machine manufacturer.

Variety of Material Solutions

At UMP Technika, we produce different waste shredders that work for all kinds of different materials. Whether your factory primarily works with paper, cardboard, wood, metal, or plastic, you’re sure to find a shredder that will suit your specific needs. Contact us to learn more about how your material can be reduced in volume and particle size.

Years of Experience

When dealing with large industrial machines with a more significant potential for hazards, it is of the utmost importance that you source your equipment from a reputable company. UMP Technika has manufactured industrial equipment for years, and we’ve proven time and time again that our products are reliable, safe, and ideal for industrial workplaces.

Products That Fit Your Needs

At UMP Technika, we understand that every company’s situation is unique and that certain problems require custom solutions. That’s why we work together with business owners to create products and make adjustments that can meet their specific needs.

Our industrial machinery comes in various distinct designs, each of which lends itself to a different purpose for optimal waste management. It’s essential to consider the design of a waste shredding machine before you buy, so you can be sure it’s the suitable model for your needs.

If you have a unique industrial waste issue, don’t hesitate to get in touch with a representative and learn how we can develop a custom solution just for you.

Ongoing Assistance

When you buy an industrial shredder from UMP Technika, our relationship doesn’t end upon delivery of the product. Our technicians are always available in the future to assist with spare part replacements, tune-ups, repairs, and general equipment maintenance. We also offer consultations to meet your unique needs.

What is the Average Cost of a Shredding Machine?

In most cases four main variables determine the price of an industrial shredder:

What material requires shredding?

Wood, hay, metal, plastics – each material behaves differently when being shredded and may require different types of shredders and blade types.

Is additional equipment needed?

Our company is happy to assist our clients with a selection of custom feeding bunkers, transporting conveyors and other equipment benefiting your efficient production process.

How much material needs to be processed per hour of work time?

Different types of shredders produce different maximum shredding volumes per work hour. Bigger, higher throughput shredders are more expensive than smaller alternatives. To give you an accurate representation of what you can expect from our equipment we offer free material testing at our manufacturing facility in Lithuania.

What is the particle size being put into the shredder and what particle size is required to come out of the shredder?

Different sizes of material require different sizes and feeding types of shredders. Long boards require horizontal feed shredders, while smaller chunks of wood work better with vertical feed shredders. Final particle size requirements also inflict the price of the product. In some cases one shredder might not be enough and two-step shredding process might be required to achieve final particle size at a quick pace.

Solve Your Industrial Waste Problems with Our High-Quality Shredding Machines Today!

Now that you know all about the fantastic benefits a waste shredding machine can bring to your factory, it’s time to get your hands on an industrial waste shredder of your very own. UMP Technika has different industrial shredding machines for sale with various designs and features, so you’re sure to find exactly what you need in our catalog. Contact us via the form above to get started!

Get a Quote

CONTACT USFrequently Asked Questions

Industrial shredders can be rather complex, thanks to their great deal of variety as well as the multitude of benefits and valuable applications they offer to users. As such, it’s only natural to have some questions about these excellent machines. Here are some of the most common questions we receive from clients about our industrial machinery.

How Much Material Can Be Put Through a Machine at One Time?

Each of our industrial shredding machines is optimized for a unique purpose, and as such, they are all distinct from one another. So, the amount of material that can be put through one machine at any given time varies from shredder to shredder and is also affected by the nature of the material itself. To determine the exact material throughput your machine can handle, you can perform a demonstration at our facility in advance.

Are These Machines Intended for Indoor or Outdoor Use?

While most shredding machines are intended for indoor use, they can be modified for your purpose at request.