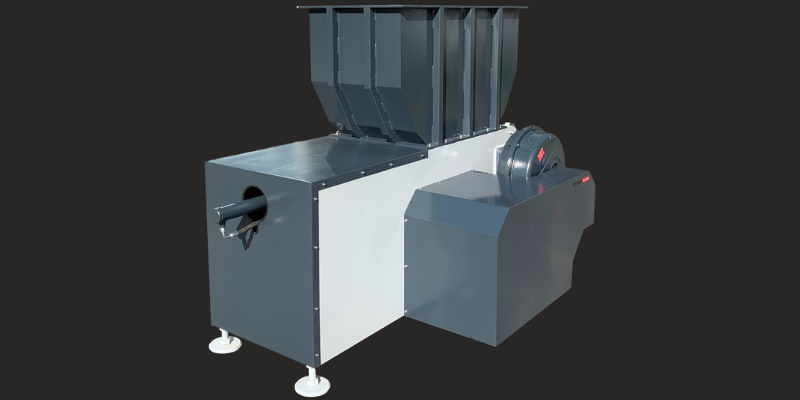

Vieno veleno smulkintuvai

Vieno veleno smulkintuvai yra vieni universaliausių šrederių. Dažniausiai naudojami medienos, ar baldų apdirbimo atliekoms smulkinti jie taip pat pritaikomi daugybei kitų medžiagų: gumai, plastikams, popieriui, spalvotiems metalams ir bendroms atliekoms įskaitant medicinines atliekas. Šis smulkintuvas leidžia medienos atliekas paversti stabilia frakcija kuri gali būti parduodama, naudojama kuro katilams, arba toliau smulkinama ruošiant ją briketavimui, ar granuliavimui. VVS siūlo daugybę patikimumo, našumo ir saugumo sprendimų randamų galingesniuose ir brangesniuose smulkintuvuose išlaikant prieinamą kainą. Keletas jų:

Horizontali hidraulinė pastūma

- Paspartina rotoriaus darbą išnaudodama maksimalų darbinį plotą.

- Valdoma išmanaus algoritmo užtikrinant saugumą ir našumą.

- Šarnynu įtvirtinta hidraulika yra patikimesnė ir atsparesnė apkrovoms.

- Rėminė konstrukcija su uždaru korpusu sugeria triukšmą, vibracijas ir užtikrina saugumą.

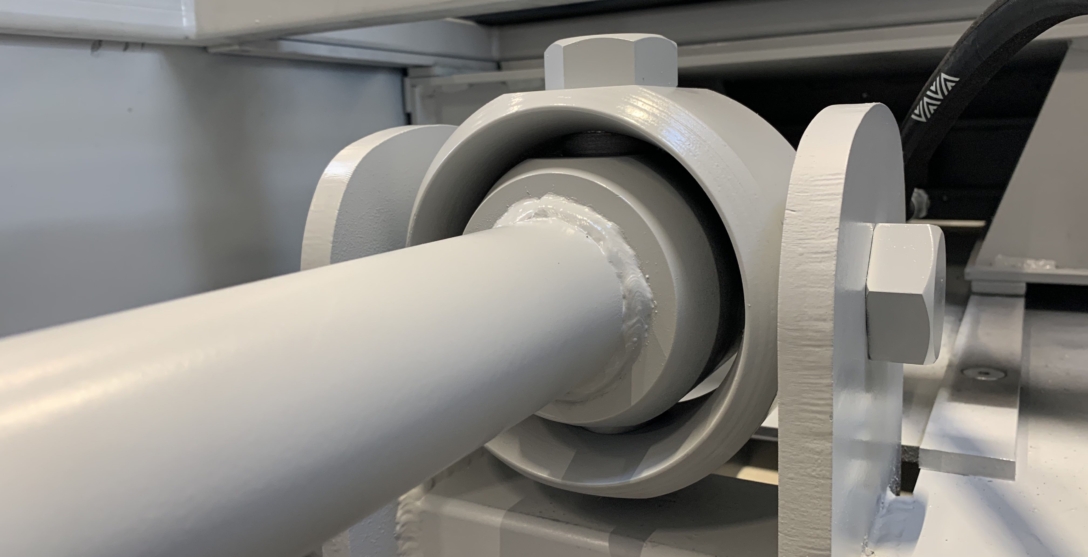

Pavara

- Elektros variklis, pavara, greičių dėžė yra apsaugoti nuo perteklinių smūgių triguba apsaugos sistema kuri yra lengvai aptarnaujama.

- Guolykla yra išnešta už korpuso ribų taip apsaugant ją nuo dulkių, šilumos ir kitų pašalinių objektų.

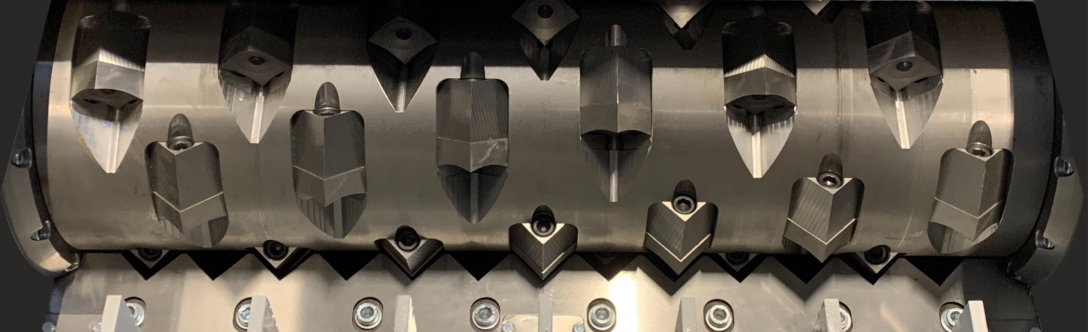

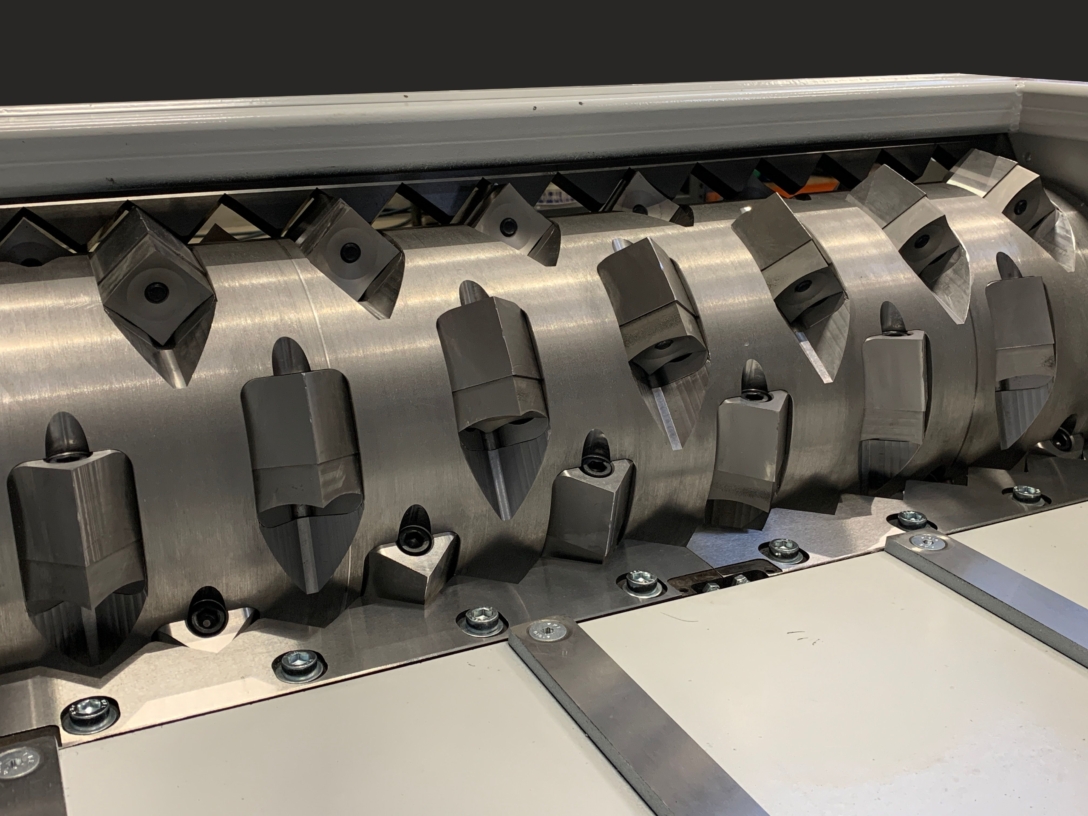

Velenas

- Darbinė veleno dalis iš vientiso aukštos kokybės plieno.

- Stipriai pažeidus darbinį veleną, ar ašis pastarosios gali būti keičiamos atskirai. Išsaugotas velenas = sutaupytos išlaidos.

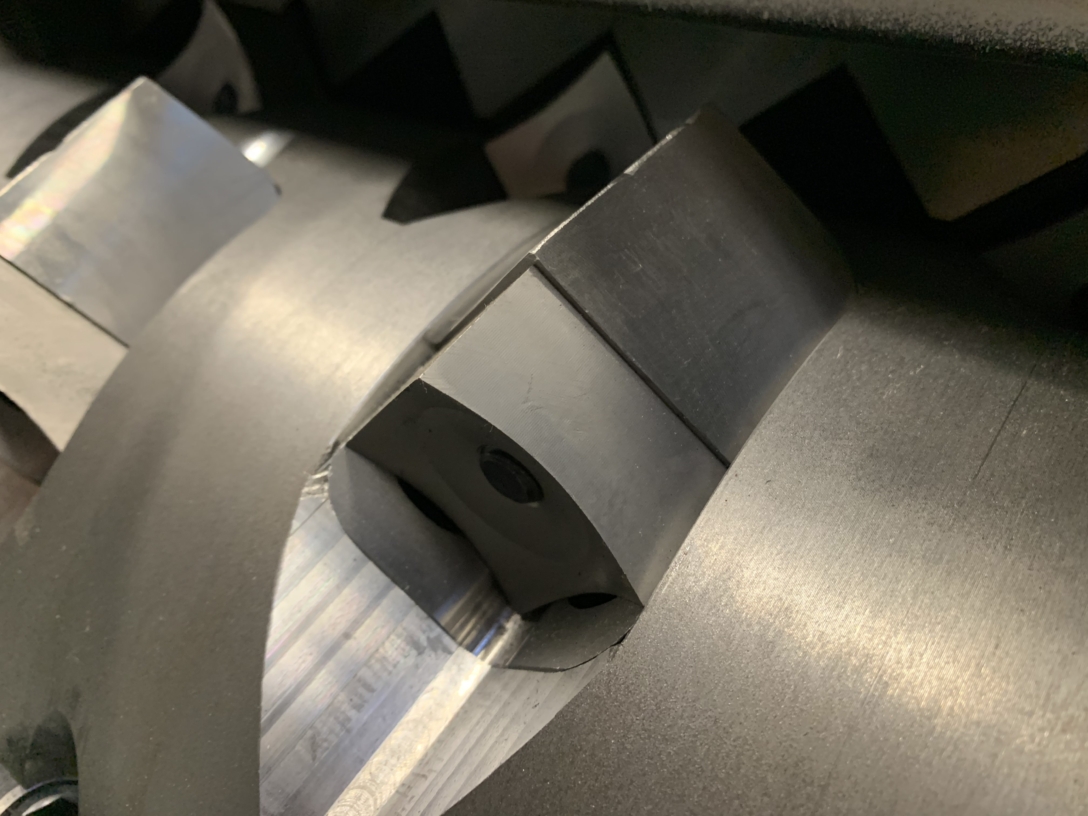

- Kitaip nei įvirinamos alternatyvos mūsu peilių laikikliai gali būti keičiami. Pažeidus peilio laikiklį pašaliniu objektu nebūtina keisti viso rotoriaus, o tik vieną laikiklį.

- 4-pusių apsukami peiliai tarnaus keturis kartus ilgiau.

- Dylant peiliams, priešpeiliai gali būti reguliuojami, kad išlaikyti reikalaujamas tolerancijas. Taip peiliai ir priešpeiliai tarnauja ilgiau prieš juos keičiant.

Našumas

- Našumas ir frakcija kontroliuojama keičiamu sietu kuris pritaikomas pagal kliento poreikius.

- Susmulkinta medžiaga pašalinama mechaniniu, arba pneumatiniu būdu.

Lietuvoje gaminama įranga, prieinamos kainos, įrodytas patikimumas, nesudėtinga priežiūra, garantija, greitas serviso ir dalių departamento darbas yra tik keletas priežasčių kodėl verta rinktis mus.

Techniniai duomenys

| VVS-600 | VVS-800 | |

| Našumas | ≤3 m^3/h | ≤3.5 m^3/h |

| Variklis | 18.5 kW | 22 kW |

| Greitis | 98 APM | 98 APM |

| Peiliai | 30 vnt | 39 vnt |

Darbinė talpa | 600x595mm | 800x595mm |

| Bunkeris | 564x1164mm | 764x1164mm |

| Ilgis | 2085 mm | 2085 mm |

| Plotis | 1248 mm | 1448 mm |

| Aukštis | 1495 mm | 1567 mm |

| Svoris | 1550kg | 1700kg |

| Maitinimas | 380 V 50Hz | 380 V 50Hz |

| Sietas | 10-50mm | 10-50mm |

| Išėjimas | 160Ø | 160Ø |