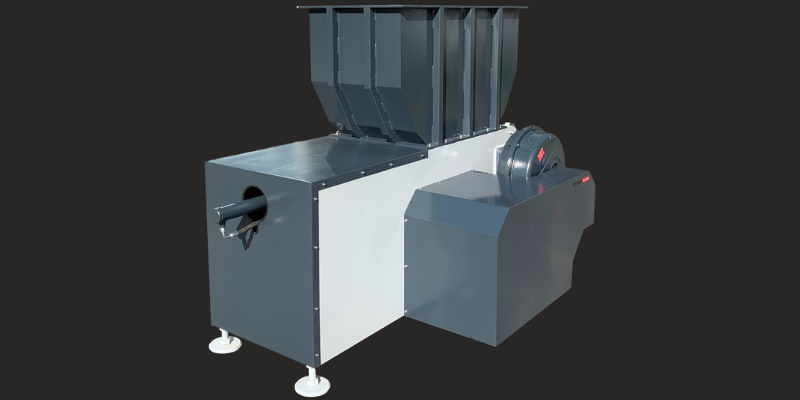

VVS family of Single-Shaft Shredders

Single rotor shredders are some of the most universal chipping platforms out there. Best known for shredding various types of wood (Briquettes, hardwood, softwood, lumber), the platform can easily be adapted to numerous other substances such as rubbers, plastics, paper, light metals and general waste (Even including medical!). Your needs are our commands. When implemented by woodworking companies into their current lineup this machine can turn woodworking and furniture making waste into briquetteable mass which is easier to store, transport and sell. Our single shaft shredders provides you with features found in much more powerful and expensive shredding units while keeping the price down to earth. A couple of them:

The horizontal hydraulic ram:

- Assists the rotor by pushing the material to provide maximum working area efficiency.

- Is controlled by an algorithm to ensure safety and efficiency

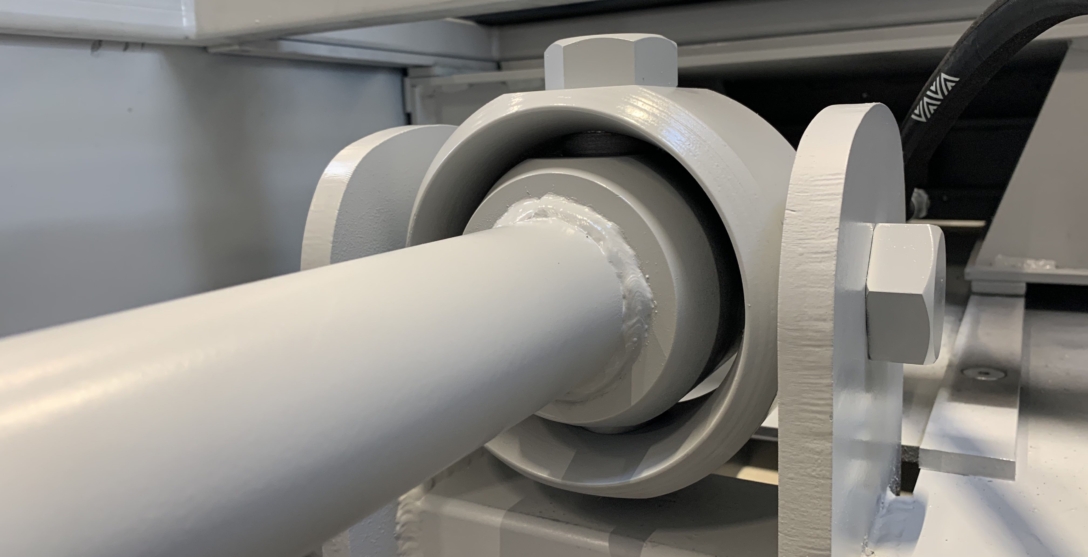

- Gimbal-mounted hydraulics provide a high lifetime

- Ladder frame chassis and enclosed hydraulics to dampen noise, vibrations and increase safety

Drivetrain

- The drivetrain is protected against hits from foreign objects by using a tripple-disengagement system which is easily resettable and serviceable.

- Offset placement of the rotor bearings keeps them away from dust and heat buildup.

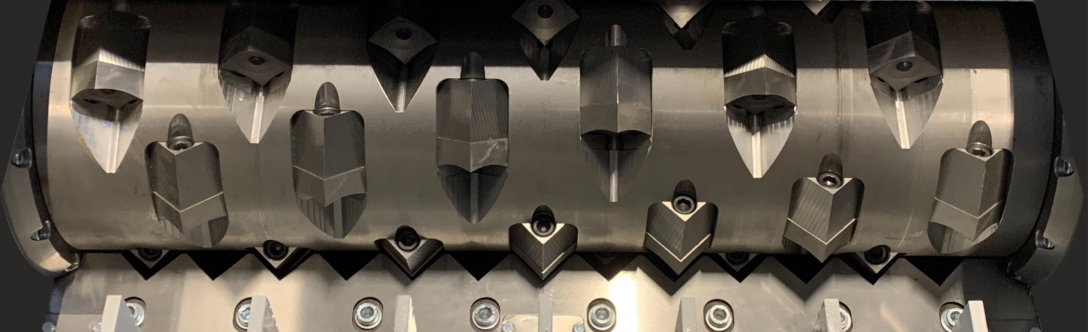

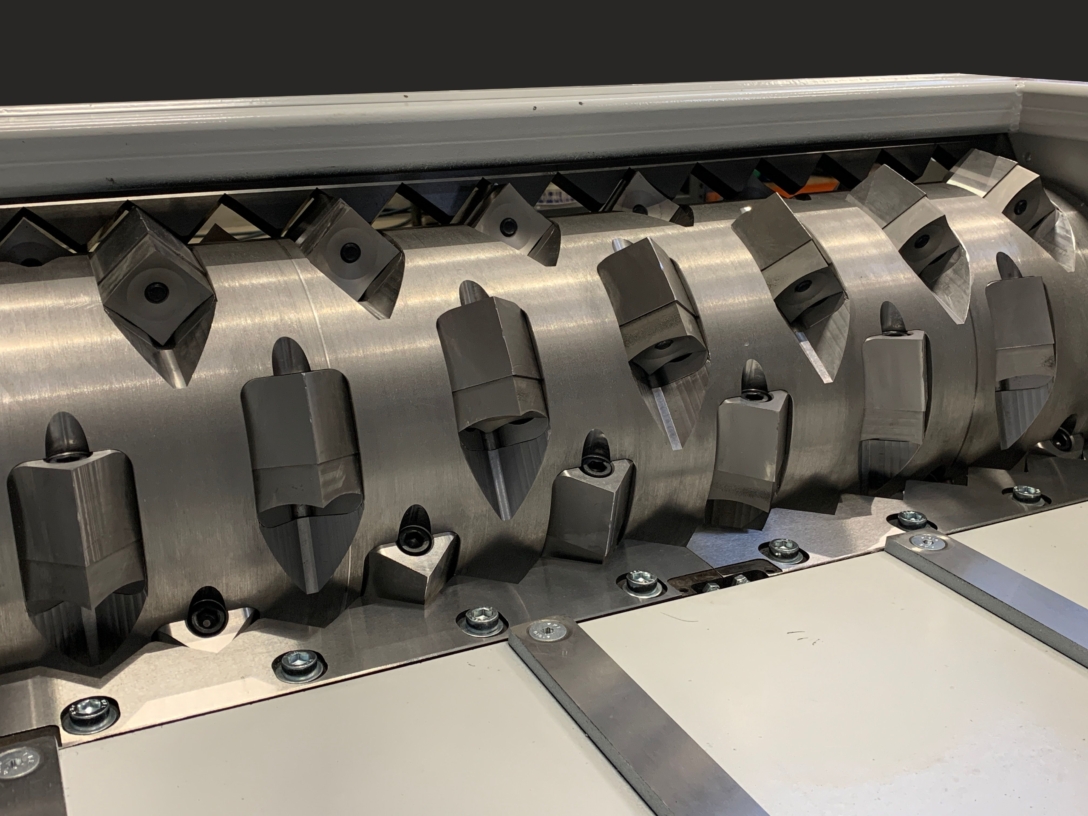

Rotor

- The centrepiece of the rotor is milled from a single block of high-grade steel.

- In case of severe damage to the rotor or its shafts, the latter can be replaced without the need to replace the whole unit – costs saved for the user!

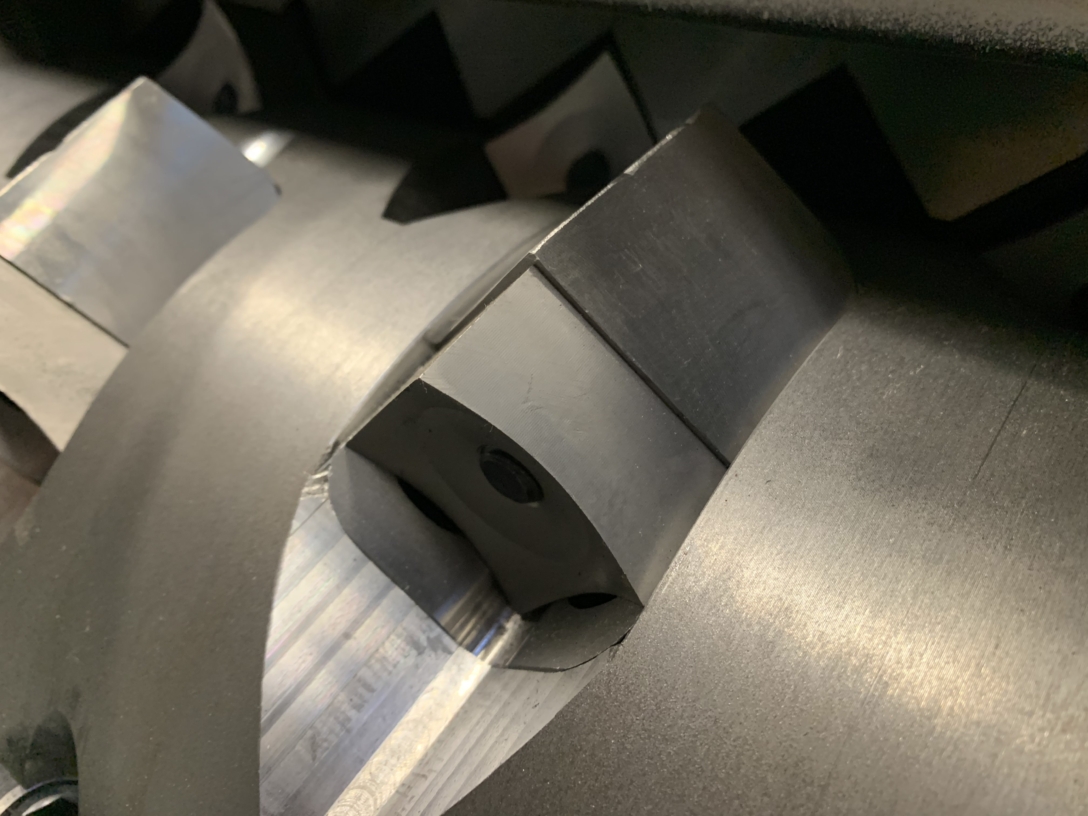

- Blade holders are replaceable – unlike welded-in options, our rotor does not need to be replaced if the blade holders get damaged.

- 4-sided rotatable blades – a single blade will last you 4 times as long.

- Our fixed blades can be adjusted to compensate for the increased tolerances once the blades start wearing out – longer runtime with a single set of blades.

Output

- Output and size is controlled by an interchangeable screen which is adapted based on the material used.

- The shredded material is removed using mechanical, or pneumatic conveyors.

Affordable pricing, proven reliability, easy maintenance, quick service and parts delivery & a warranty – these are just a couple of reasons why choose us.

Technical data

| VVS-600 | VVS-800 | |

| Output | ≤3 m^3/h | ≤3.5 m^3/h |

| Main motor | 18.5 kW | 22 kW |

| Revolutions | 98 APM | 98 APM |

| Blades | 30 vnt | 39 vnt |

Cutting area | 600x595mm | 800x595mm |

| Hopper | 564x1164mm | 764x1164mm |

| Lengh | 2085 mm | 2085 mm |

| Widh | 1248 mm | 1448 mm |

| Height | 1495 mm | 1567 mm |

| Weight | 1550kg | 1700kg |

| Power | 380 V 50Hz | 380 V 50Hz |

| Output screen | 10-50mm | 10-50mm |

| Output hole | 160Ø | 160Ø |