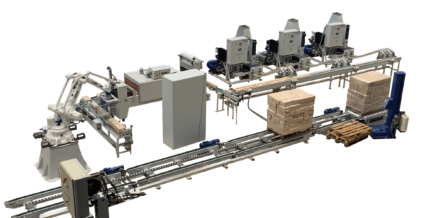

A waste paper briquette press machine allows you to turn the stray material back into usable material. Transform your scraps into functional, money-saving material with the invaluable paper briquetting press and save time and money as a result!

Our Paper Briquetting Solutions

Have a Question?

CONTACT USWhy Should You Consider Making Paper Briquettes?

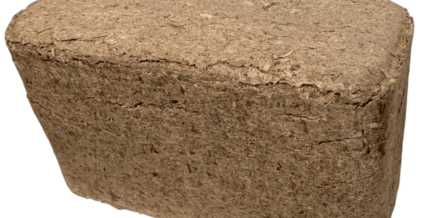

Adopting paper waste briquetting into your company model is the next best thing to printing your own cash. Paper making companies who regularly find themselves with unusable scrap paper and cardboard can now utilize our machines to create paper briquettes. The savings generated from this cardboard briquetting machine will reduce your operational cost and allow your business to become greener while doing so.

Large shredding companies and paper making companies may benefit the most from our paper scrap briquetting process. Our paper and cardboard waste briquetting machines increases efficiency by reducing the area your bales of shredded waste take up. Imagine being able to significantly reduce your frequency of trips to recycling centers or points of sale simply by transitioning to a briquetting system.

Waste Paper Briquetting Advantages

The advantages of scrap and cardboard briquetting are numerous.

Safer work environment

You will immediately reduce the volume of your waste material and the emission of dust particulates in the area, creating a safer work environment for your employees. Our scrap and cardboard briquette press is capable of high pressing power, giving you the option of briquettes with incredible density. These cardboard briquette machine presses can operate at top efficiency as consistently as your company.

Ability to re-use and resell

Operations that result in waste materials must inevitably decide on how to handle them. Without our briquetting machine on your factory floor, your options are too often restricted to disposal. Incorporating our waste briquetting press expands your possibilities for reuse and resale, revolutionizing your waste management process.

Reduce storage and transportation costs

Even if you decide to recycle the briquette material you generate with our press, there is money to be made from its inclusion in your operations. This is the perfect piece of equipment to reduce storage and transportation costs for your facilities.

Need more information?

CONTACT USOur Briquetting Machines for Other Types of Materials

If your shop or factory uses works with multiple materials, good news: we offer recycling solutions across the board. In addition to a paper & cardboard briquette machine, you might consider:

The same briquetting power and capabilities as our paper briquette maker, hydraulic briquetting presses can be applied to wood without sacrificing any of its efficiency.

Creates briquettes from straw, hay, tobacco, and other secondary waste products of the farming industry.

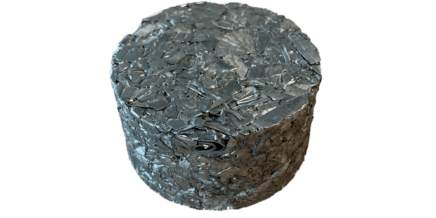

Metal Briquetting Machines

Need something stronger than our paper briquette maker press and our wood briquetting machine? We’ve got you covered with our metal briquetting machines.

Don’t Let Any More Profits Get Swept Away!

Whatever your needs, UMP Technika has the right industrial machine to optimize your operations. Contact us now to immediately start transforming your factory floor into a greener, more profitable operation.

Frequently Asked Questions

If you are considering purchasing one of our briquetting presses and you still have some questions, don’t worry. We’ve prepared a list of our most frequently asked questions to try and give you a better insight.

How Does the Paper and Cardboard Briquette Press Work?

A paper and cardboard briquette maker works by allowing you to place your scrap materials in its feed tray, where it is funneled into the pressing mechanism. The materials are then compressed at intense pressure, forming dense briquettes before sliding them into a safe retrieval area.

How Large is the Briquette Press Machine?

It might be a better question to ask how small our briquette press is. The press only requires an 1800 mm x 1800 mm x 1900 mm area to operate, relatively small in terms of industrial equipment.

How Fast Can the Machine Press Briquettes?

Our briquette presses are ready to work as efficiently and quickly as you do. This means our presses are capable of producing almost 600 briquettes an hour. If you have the scraps, the machine will work furiously to get those profits back into your pockets quickly.